Benner Acoustic panels (alsoknown as sound absorption panels,soundproof panelsorsound panels) are sound-absorbing fabric-wrapped boards designed to control echo andreverberationin a room.

Benner Acoustic Panels are highly aesthetic and popularly customized. Our panels offer an elegant and economical sound absorption solution.

Benner Acoustic Panels offer a variety of sizes and shapes available in over 50 colors. Our panels provide ideal results for noise control and are impressively decorative which allows them to accommodate to any workable environment. Our Glass Fiber panels are covered with an acoustically transparent and very decorative fabric, the fabrics allow for the variety in colors as well as variety in the texture of the fabric. The fabrics that are used are offered in an assortment of different textures. Benner Acoustic Panels are ideal for spaces with high reverberation time. Our panels are designed to improve sound quality and to provide a decorative look within a room.

Manufactures Standard panel construction consisting of facing material stretched over front face of edge-framed, dimensionally stable, rigid glass-fiber board core and borders or attached to edges and back of frames and complying with the following requirements:

• Facing Material: Stretched Panel Fabric Guilford of Maine FR 701 Style 2100 (or other fabrics of similar characteristics).

• Nominal core Density: 4-7 lbs /Ft3 (64 – 112 Kg/m3).

• Framing: Manufacturer´s standard metal or wood framing system. No plastic frame.

Woodwork Wonders: Diverse and Dependable

Our Wood Screws are a testament to our commitment to versatility and quality. From flat to bugle heads and coarse threads, each screw is designed to provide a strong, reliable hold in various types of wood. Available in multiple lengths, these screws are perfect for woodworking projects that call for both finesse and strength.

Packaging Options for Every Need

At Benner Screws, we recognize the diversity of your project needs and have tailored our packaging options to match. Whether your task is large or small, we offer the flexibility required to ensure you have the right amount of high-quality screws at your fingertips. Choose from our convenient 1-pound boxes for those smaller projects or individual needs. For more extensive construction work or to keep your workshop well-stocked, our 40-pound master boxes provide an economical solution, offering a discounted rate for bulk purchases. Embrace the efficiency and value of buying in bulk with Benner Screws, where quality meets practicality in every box.

Benner Screws: The Foundation of Every Great Project

With Benner Screws, you’re not just buying a product; you’re investing in a solution that brings your projects to life. Our dedication to quality, combined with a wide range of options and sizes, ensures that we have the right screw for every application. Dive into our collection and experience the difference of working with screws that are designed to deliver.

Metal Frame Solutions: Precision and Strength

Our Metal Frame screws, including sharp-point framing, self-drilling, and self-tapping options, are engineered for seamless integration into your projects. Whether you’re connecting frame to frame or seeking the perfect drywall screw, our products promise ease of use and exceptional hold.

Drywall and Metal Frame Mastery

Transition smoothly from frame to gypsum or cement board with our specialized Drywall Metal Frame screws. With sharp and self-drilling points available, and sizes ranging to suit various thicknesses, we’ve got every aspect of your drywall project covered.

Concrete Confidence: Hex and Flat Head Options

For those demanding concrete applications, our Concrete Screws are ready to anchor your projects securely. Available in both hex and flat head designs, these screws come with the drill bit included, ensuring you have everything you need for a swift, effective installation.

Woodwork Wonders: Diverse and Dependable

Our Wood Screws are a testament to our commitment to versatility and quality. From flat to bugle heads and coarse threads, each screw is designed to provide a strong, reliable hold in various types of wood. Available in multiple lengths, these screws are perfect for woodworking projects that call for both finesse and strength.

Packaging Options for Every Need

At Benner Screws, we recognize the diversity of your project needs and have tailored our packaging options to match. Whether your task is large or small, we offer the flexibility required to ensure you have the right amount of high-quality screws at your fingertips. Choose from our convenient 1-pound boxes for those smaller projects or individual needs. For more extensive construction work or to keep your workshop well-stocked, our 40-pound master boxes provide an economical solution, offering a discounted rate for bulk purchases. Embrace the efficiency and value of buying in bulk with Benner Screws, where quality meets practicality in every box.

Benner Screws: The Foundation of Every Great Project

With Benner Screws, you’re not just buying a product; you’re investing in a solution that brings your projects to life. Our dedication to quality, combined with a wide range of options and sizes, ensures that we have the right screw for every application. Dive into our collection and experience the difference of working with screws that are designed to deliver.

Cleaning and Maintenance

These panels are designed for long term use in building environments with minimal maintenance. These panels, however, can be vacuum cleaned as per customer desire; additionally, any marks may be cleaned with a damp cloth/wipe.

Fire Resistance

All our panels are classified as Class A or Class 1 laboratory tested as per ASTM- E84. ). Smoke developed: 50.

Technical Properties

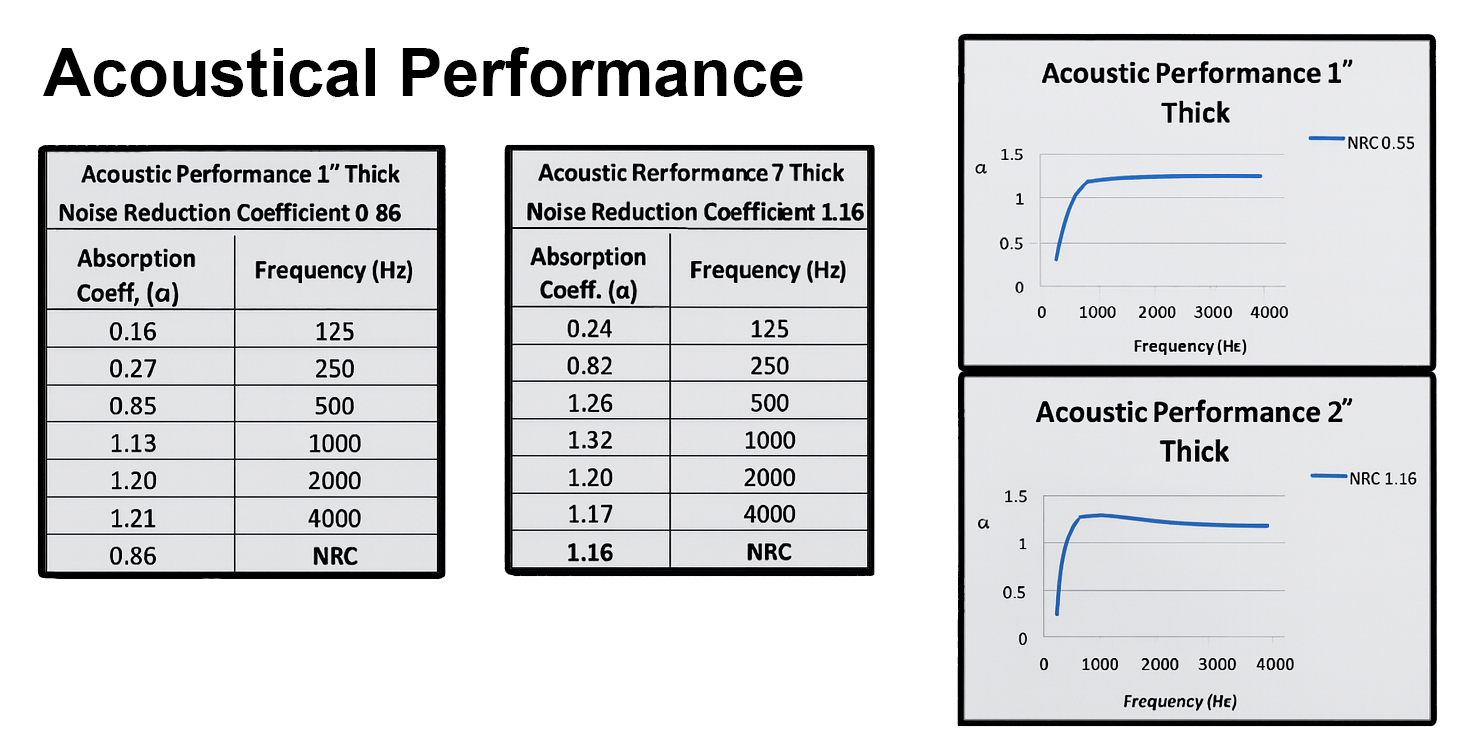

•Panel Thickness: Manufacturer´s Standard

•2″ inches Rigid Fiber-Glass

•1″ inches Rigid Fiber-GlassPanel

•Widths: 24″, 48”, or custom

•Panel Height: 2’, 4’, 6´, 8´, 9´, & 10´

•Edge detail: Square or custom

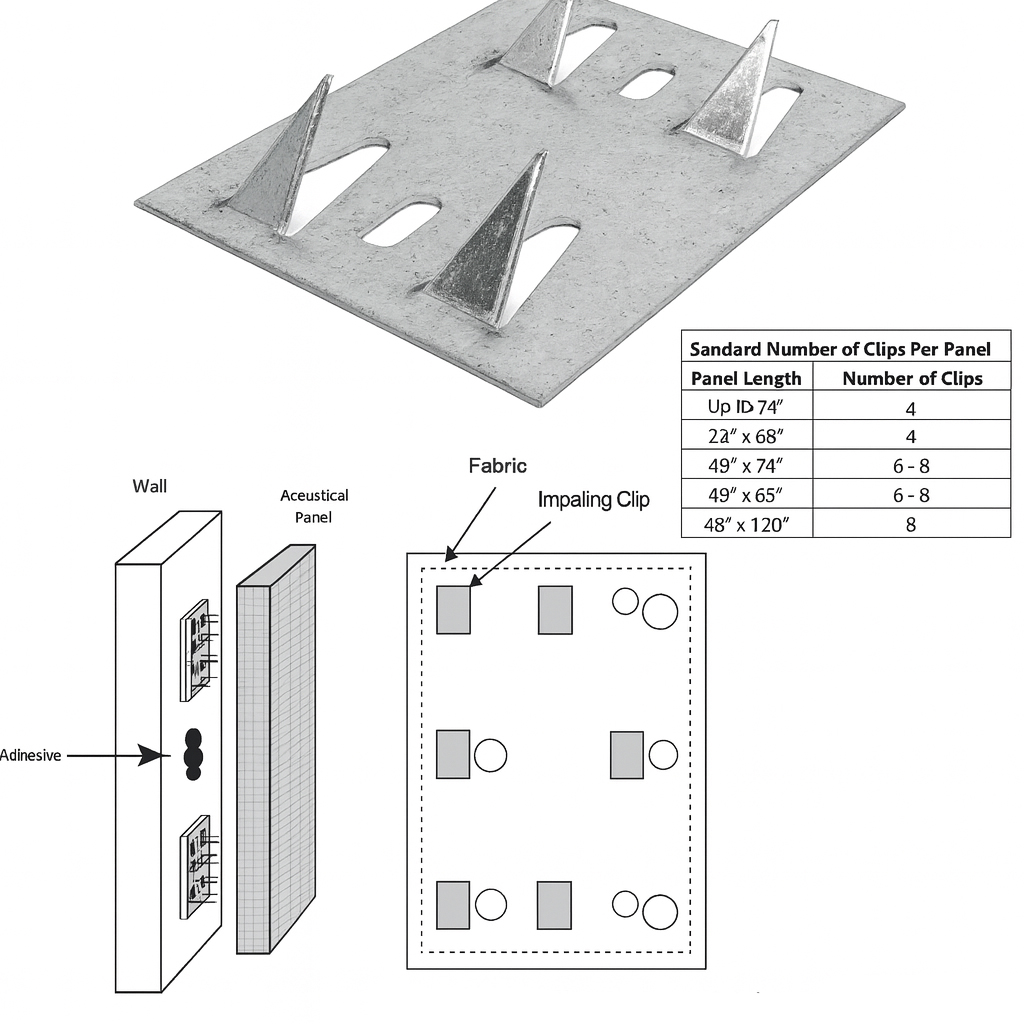

Impaling Clips Option

If the wall panels are not required to be removable, the easiest method of installation is impaling clips. Impaling clips are shipped from the factory with the panels.

- Should be screwed into the wall where the panels are to be installed. Care should be taken to screw the impaling clips into a stud when possible and to space the clips so that they will be evenly spaced on the back of the panel.

- The back of the wall panel should be covered with a construction adhesive(Liquid Nail PL 200, Chemrex 200, etc) and placed onto the wall in the desired location.

Caution: Adhesive skins over rather quickly, in perhaps two minutes or less and loses a great deal of its penetrating ability. Therefore, it is important that the adhesive be applied quickly to the panels and then quickly applied to the mounting surface, one panel at a time.