We represent in the United States the brand DuROCK Alfacing International LTD of Canada, with more than 40 years, they have been a leading manufacturer of top quality products in the field of Exterior Insulation Finish Systems (EIFS), and Specialty Coatings for floors and walls. The company’s broad range of products and wall systems are subjected to extensive research and rigorous testing to ensure that they meet United States requirements.

These Exterior Insulation Finish Systems are recognized for maximizing energy efficiency and reducing moisture penetration. These systems are virtually maintenance free and are very cost competitive. It is the flexibility of colour, shape, texture and dimension that has stimulated architects, and designers to create new and exciting modern designs.

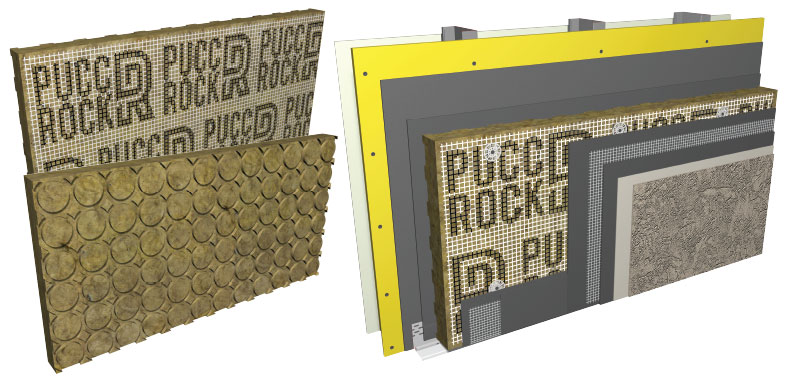

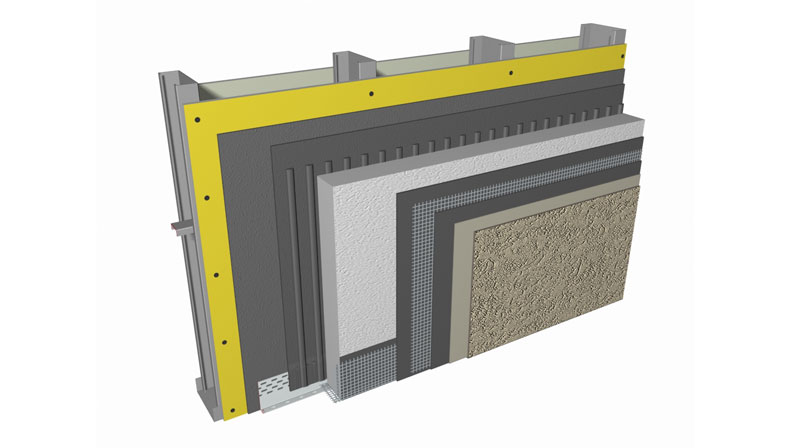

PUCCS NC (NON-COMBUSTIBLE) CLADDING

DuROCK’s PUCCS NC is the latest addition to the PUCCS series of Exterior insulated Finish Systems. The GDDC circular grooved PUCC-ROCK virgin wool insulation board has a 10mm deep air space required by building code and professional insurers. PUCC-ROCK non-combustible insulation and its integral reinforcing mesh are simultaneously fastened to the supporting wall using DuROCK’s liquid applied WRB’s and mechanical fasteners. The PUCC-ROCK insulation board effectively forms a water-repellant gasket around each fastener. PUCC-ROCK insulation boards are face-marked at 4 inch intervals to pinpoint stud locations, which makes this system much easier and faster to install. PUCCS NC has dual reinforcing meshes for increased impact resistance. PUCCS NC liquid-applied WRB’s effectively control air leakage, yet permit vapour diffusion to the exterior. PUCCS NC can be easily detailed to direct precipitation to the exterior.

Additional Documents: 3D ILLUSTRATIONS FULL PACKAGE – 2D DETAIL FULL PACKAGE – AUTOCAD DRAWINGS

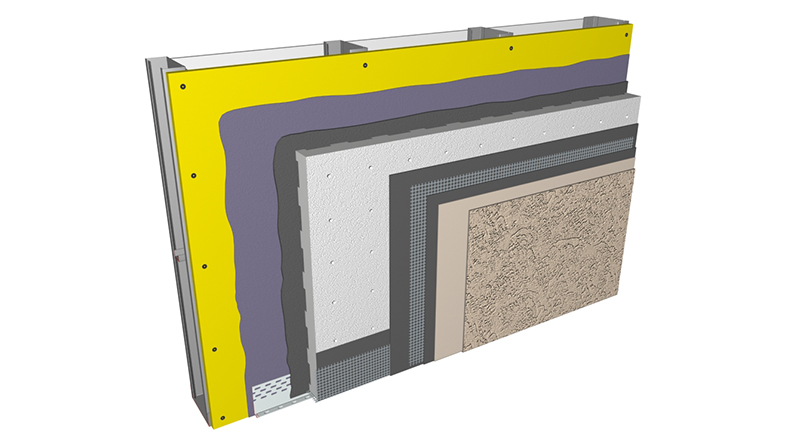

PUCCS EIFS FOR COMMERCIAL AND HIGH RISE

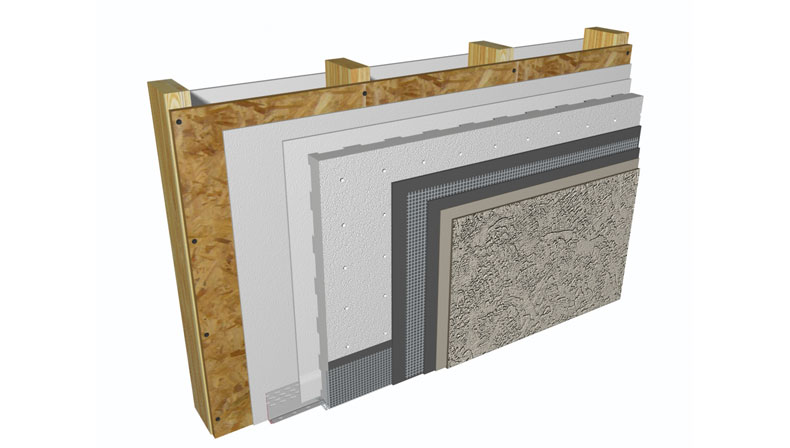

PUCCS EIFS FOR RESIDENTIAL AND LOW RISE

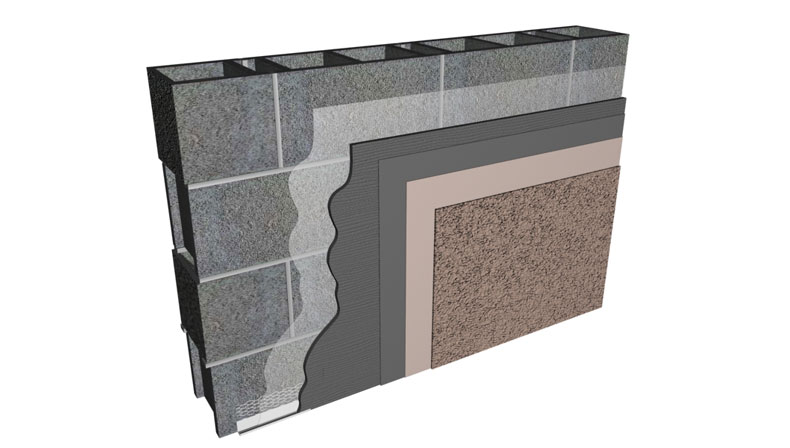

PUCCS EIFS FOR INSULATED CONCRETE FORM (ICF)

DUROCK INSULROCK/COMMERCIAL & HIGH RISE CONSTRUCTION

The DuROCK series of InsulROCK EIFS provides moisture control through the use of a secondary barrier to moisture intrusion, which may also be used to control air leakage. This barrier, combined with the system’s ability to drain incidental moisture, makes InsulROCK EIFS well suited for cladding buildings of any size. The DuROCK InsulROCK System is intended for use on non-wood substrates. This system may incorporate either DuROCK Cement Bear (air/moisture barrier) or, where the design permits, DuROCK Vapour Block.

DOWNLOAD DOCUMENTS: SPEC– 3D DETAIL– 2D DETAIL– AUTOCAD – CCMC EVALUATION

DUROCK STUCCO PLUS FOR SHEATHING SUBSTRATES

Stucco Plus incorporates a polymer-enhanced, fiber-reinforced base coat for superior adhesive and cohesive strength, as well as a polymer-based finish which is available in a variety of textures and infinite colors. The stucco base coat is supported by and reinforced with mechanically attached metal lath. Please refer to the system specification and appropriate details for further information.

DUROCK STUCCO PLUS RS RAINSCREEN SYSTEM

Stucco Plus RS is Stucco Plus with a rainscreen. The rainscreen incorporates a drained air space that separates the cladding system from the supporting construction. The Stucco Plus RS details illustrate a drained air space created through the use of wood strapping. Please refer to the system specification and appropriate details for further information.

Additional Documents: SPEC – 3D DETAIL– 2D DETAIL– AUTOCAD

DUROCK STUCCO PLUS FOR MASS WALL SUBSTRATES

Stucco Plus does not require metal lath when installing over concrete or masonry provided the surface is clean, dry, and free of any material such as paint, wax, or oil that may inhibit adhesion, and provided the substrate is conditioned with DuROCK Jewel Stone Primer prior to application of the base coat. Please refer to the system specification and appropriate details for further information.