The Best Investment for Your Pocket!

This is a Informative Article on Duct Insulation – To view our product Benner Duct Insulation CLICK HERE

Introduction

A reflective insulation typically performs as a system that incorporates one or more highly reflective (low emittance) surface(s) adjacent to an enclosed air space. Reflective insulations are typically installed on the outside of a duct using spacers to create an enclosed air space between the outer surface of the duct and the low emittance surface of the reflective insulation. When installed in this manner, reflective insulations can effectively reduce heat loss from ducts and can prevent warm, moist air from being drawn into return ducts and coming into contact with cold duct surfaces.

The key to maintaining a comfortable, energy efficient living environment in a home or building is to reduce the heat loss in the winter and to minimize cooling loads in the summer. One way to improve the energy efficiency of a home or building is to improve the efficiency of the duct system. Ducts are usually made from sheet metal or flexible plastic material. A duct system circulates warm and cool air throughout a home or building. Typical duct systems can lose 25 to 40 percent of the heating or cooling energy emitted by the central furnace, heat pump, or air conditioner. According to the U.S. Environmental Protection Agency, leaking ducts can decrease the overall efficiency of a home’s heating and cooling system by as much as 20 percent. Recent research funded by the Department of Energy (DOE) and CIEE through Lawrence Berkeley National Laboratory (LBNL) has found that typically, a quarter of the energy used for heating and cooling is wasted through duct system energy loss. Sealing ducts can increase the ability of air conditioners, furnaces, and heat pumps to evenly heat and cool all of the rooms in a home or building. Using reflective insulation systems to reduce heat loss during cold seasons and to prevent warm moist air from being drawn into leaky return ducts during hot, humid seasons can enhance the efficiency of duct systems.

In many places in the country, ducts are located in attics, crawl spaces, garages, basements (unoccupied) and other locations where significant heat is lost. Duct leakage accounts for much of the inefficiency of residential forced-air heating and cooling systems. Duct systems lose energy through some of the following mechanisms:

- Conduction: Warm air inside ducts heats duct walls, which in turn heat the cold air outside the duct. If the duct is located in an attic or crawl space, the heat is completely lost.

- Air Leakage: Accidental holes in ducts or poorly connected duct sections will result in loss of efficiency. Duct system pressure is critical to the efficiency of any forced-air-space-conditioning system. For example, a furnace fan produces a high pressure in the supply ducts and a low pressure in the return ducts. The high-pressure forces warm air from the supply ducts to flow into the rooms, and low pressure draws room air back into the return ducts.

- Leaky Supply Ducts: Energy is lost when air warmed by the furnace is lost and when it is replaced. In other words, the energy is lost when the warm air does not go to the rooms and when extra energy is needed to heat cold air that is leaked into the house as a result of air pressure changes.

- Leaky Return Ducts: When return ducts leak, cold air from outside is pulled into the duct. This cold air is heated in the furnace along with the air inside the house that is pulled through the return registers. To equalize flows, heated room air leaks out of the house through the same holes and cracks that allow cold air to leak in. Most residential forced-air-distribution systems in the United States have their ducts located in an attic or crawl space that is not conditioned. During the cooling season in hot, humid climates, leaky return ducts located in an attic or crawl space can allow a significant amount of moisture into the air in the house without increasing the temperature significantly. As a result, the air conditioner will satisfy the thermostat, but the humidity inside the house will increase.

Signs of Problem Ducts

There are a number of signs that may be indicative of duct energy loss or inefficiency. The following are examples of potential problems associated with ducts:

- Uninsulated Ducts in Unconditioned Spaces: If the duct system passes through an attic or unventilated crawl space, then significant energy can be lost.

- Torn or Damaged Ducts: Holes that are large enough to see. Also, flexible ducts may be damaged if weight is placed on them.

- Disconnected Ducts: If duct tape was used to seal joints between duct sections, it often loses adhesiveness after a few years and may fall off or peel easily.

- Leaky Duct Section Joints: Dust or soot may accumulate over time at areas where air is being pulled into the duct.

- Condensation: The prevention of water vapor condensation on duct systems is as important as the energy savings achieved by reflective insulation duct systems. Cold air inside an air-handling duct system is often below the dew-point temperature of the air surrounding the duct. This is generally the case during the cooling season.

- Reflective Duct Insulation Systems: Reflective insulation systems have exterior facing material with near-zero permeance. Water vapor does not move through the intact aluminum foil because the permeance is near zero. Taping of seams during the installation process prevents water-laden air from coming into contact with the duct surface.

The second objective is to maintain the outside surface temperature of the reflective system above the dew-point temperature of the surrounding air. The insulation surface temperature will be between the warm outside temperature and the temperature inside the duct. Increasing the reflective insulation’s surface-to-surface thermal resistance will reduce the temperature difference between the surrounding air and the insulation surface. The thermal resistance needed to prevent condensation for specific exterior air conditions and the temperature of the air inside the duct can be readily calculated. A reflective insulation surface-to-surface R-value of 3, for example, would generally mean that the steady-state temperature of the outside insulation surface will be colder than the outside air temperature by about 1/3 of the difference between the inside and the outside air temperatures. This result. Movement of air on the warm side will increase the outside surface temperature, thus bringing it closer to the outside air temperature. This is generally favorable for preventing surface condensation.

When the dew-point temperature for air at 100% relative humidity is the same as the dry-bulb temperature, condensation will occur. As the relative humidity decreases, the dew-point temperature decreases. The dew-point temperature is 64.6°F for air at 75°F and 70% relative humidity. This means that keeping the surface temperatures above 64.6°F will prevent surface condensation for the conditions stated.

Installation Guidelines For Reflective Insulations

- Pre-Installation Inspection and Preparation: In areas where insulation is to be installed, components of the duct system shall be free from defects and leaks. Exfiltration at joints will cause condensation in the cooling mode and reduced thermal resistance of the insulation system in both modes. If the duct system is found to be faulty, repairs shall be completed prior to the installation of the reflective insulation.

- Installation: Reflective insulation systems designed for use on air-handling systems reduce heat loss or gain to the air in the ducts and prevent condensation due to warm-humidity air coming into contact with cold duct surfaces. In order to accomplish these objectives, the manufacturer’s installation instructions must be followed. The important factors related to reflective insulation installation are discussed below. A pre-installation inspection is an important first step in the installation process. Ducts with mechanical defects should be repaired before insulation is installed.

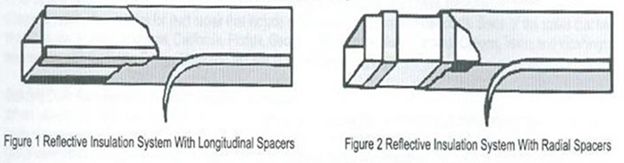

Reflective insulation systems utilize closed air spaces to provide a major part of the system R-value. Reflective insulation systems for air-handling systems usually consist of spacer material to provide an enclosed air space between the outside duct surface and the reflective insulation installed around the duct. Various types of spacers are used for this application. The air gap between the duct and the reflective insulation is generally 1/2 to 1 inch thick. The spacer design may be either continuous strips or short pieces positioned to assure the air gap. The specification of the spacer material and method of applying to the duct is an important part of the reflective insulation system design. Please refer to the manufacturer’s literature for this information. Spacer installation instructions must be followed in order to achieve the labeled system R-value.

The drawings shown in Figures 1 and 2 below represent the two options for installation of spacer materials.

The following information is intended as a guide only and does not replace the manufacturer’s installation instructions.

- The reflective insulation shall be handled in accordance with the manufacturer’s instructions and should be kept free of extraneous material.

- The manufacturer’s installation instructions and local building codes shall be followed to ensure proper installation. The thermal performance of a reflective insulation system is based on the maintenance of an enclosed air space between the duct and the adjacent low emittance surface of the reflective insulation.

- The thermal performance of a reflective insulation system depends on adherence to the manufacturer’s instructions for spacer positioning, spacer dimensions, spacer material and air space dimensions.

- Consult the manufacturer’s installation instructions for the proper method of sealing and fastening seam edges and joints. Use only UL 181 approved pressure sensitive tapes and sealants.

- The thermal performance of a reflective insulation system will be diminished if there is not a good seal around duct hangers or clamps. Consult the manufacturer’s installation instructions for directions on sealing around hangers and clamps.

Repair of Heating and Cooling Air Ducts

- Most duct leakage could be prevented with proper duct sealing. But field examinations often reveal seals failing over time. The best choice of duct sealant will vary by climate, construction type, and local experience. Unsealed or poorly sealed ducts can result in a loss of energy efficiency in a home. The following information is intended as a guide only. Consult the manufacturer’s installation instructions for specific repair information:

- Clean Duct Surfaces

- Use a clean cloth to wipe dust from the surface of the duct. If there is an oil or grease film on the duct, use a damp cloth to clean the surface.

- Joints With Less Than 1/4 Inch Gaps

- Use a brush to apply mastic to seal the gap (use UL181A-M or UL181B-M approved mastics). Coat the entire joint with a continuous strip of mastic. Use the end of the brush to work the mastic into the joint. Spread mastic at least one inch on each side of the joint.

The mastic should be thick enough to hide the metal surface of the duct (about 1/16″ thick).

- Joints With Gaps Greater Than 1/4 Inch

- If the gap in the duct connection is larger than 1/4 inch, use a fiberglass reinforcing membrane in addition to mastic. If the membrane is sticky on one side, cut enough membrane to cover the joint and press the membrane in place and cover with mastic. Apply enough mastic to completely cover the membrane. If the membrane does not have a sticky side, first apply a thin layer of mastic, press the membrane into the mastic and then apply the finish layer of mastic.

- Wrap Ducts With Insulation

- A reflective insulation system can be installed as described in the previous section.

Duct Repair Programs

- Leaking ducts can decrease the overall efficiency of a heating and cooling system by as much as 20%. The typical family can save up to $140 annually by properly sealing leaks in ducts. Several utilities companies have implemented duct sealing programs designed to provide incentive for duct repair that include cash incentives to cover repair costs. Some of the states that have initiated programs are: Arizona, Arkansas, California, Florida, Georgia, New Jersey, North Carolina, Oregon, Texas, and Washington. For more information, visit the Home Energy Magazine website at www.homeenergy.org.

Building Code Requirements For Duct Insulation Materials

- When selecting construction materials for use in buildings, it is important to confirm that all materials comply with applicable building code requirements. Reflective insulation materials are typically evaluated to confirm compliance with the new International Code Council (ICC) International Residential (IRC), Building (IBC), Mechanical (IMC), and Plumbing (IPC). Each Code has specific sections that address requirements for materials used to insulate ducts. The Codes typically reference requirements relating to thermal and fire performance. The following chart describes the building code requirements for materials used to insulate ducts.

| Code Section | Applicable Code/Section | Test Method | Requirement |

| Surface Temperature (Section 604.2) | International Mechanical Code | ASTM | Ducts that operate at temperatures exceeding 120°F (49°C) shall have sufficient thermal insulation to limit the exposed surface temperature to 120°F (49°C). |

| Coverings and Linings (Section 604.3) | International Mechanical Code | ASTM E 84 | Maximum Flame Spread and Smoke Developed Ratings of 25/50. Duct coverings and linings shall not flame, glow, smolder or smoke when to a temperature of 250°F (121°C). |

| Surface Burning | International Mechanical Code | ASTM C411 | Foam plastic shall conform to the requirements of Section 604 and the International Building Code. This criteria applies only to duct insulation materials that are foam plastic (bubble pack materials are not foam plastic). |

| Temperature Exposure (Section 604.7) | International Mechanical Code | UL181 | Duct insulations must be labeled at intervals not greater than 36 inches (914 mm) with the name of the manufacturer, R-value, flame spread and smoke developed ratings. |

| Identification (Section 604.13) | International Mechanical Code | UL181 | Insulations used as internal insulation (duct liner) and exposed to the airstream in ducts shall be shown to be durable when tested in accordance with UL181. |