Benner Reflective Insulation

Benner Reflective Insulation & Duct Wrap when installing its primary function to reduce heat gain and reduce cooling costs. The barriers consist of a highly reflective material that reflects radiant heat rather than absorbing it.

HOW BENNER REFLECTIVE INSULATION WORKS

Heat travels from a warm area to a cool area by a combination of conduction, convection, and radiation. Heat flows by conduction from a hotter location within a material or assembly to a colder location, like the way a spoon placed in a hot cup of coffee conducts heat through its handle to your hand. Heat transfer by convection occurs when a liquid or gas — air, for example — is heated, becomes less dense, and rises. As the liquid or gas cools, it becomes denser and falls. Radiant heat travels in a straight line away from any surface and heats anything solid that absorbs its energy.

Most common insulation materials work by slowing conductive heat flow and convective heat flow. Radiant barriers and reflective insulation systems work by reducing radiant heat gain. Dust accumulation on the reflective surface will reduce its reflective capability. The radiant barrier should be installed in a manner to minimize dust accumulation on the reflective surface.

When the sun heats a roof, it’s primarily the sun’s radiant energy that makes the roof hot. Much of this heat travels by conduction through the roofing materials to the attic side of the roof. The hot roof material then radiates its gained heat energy onto the cooler attic surfaces, including the air ducts and the attic floor. A radiant barrier reduces the radiant heat transfer from the underside of the roof to the other surfaces in the attic.

A radiant barrier works best when it is perpendicular to the radiant energy striking it. Also, the greater the temperature difference between the sides of the radiant barrier material, the greater the benefits a radiant barrier can offer.

Benner Radiant Barrier – Reflective Insulation

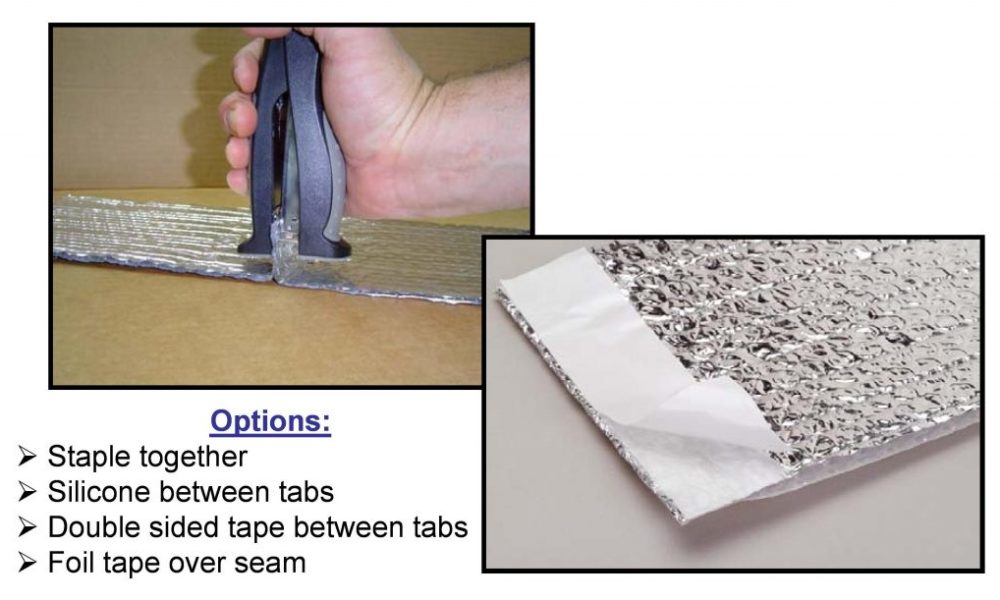

Benner Reflective Insulation must always be installed in the presence of air space.

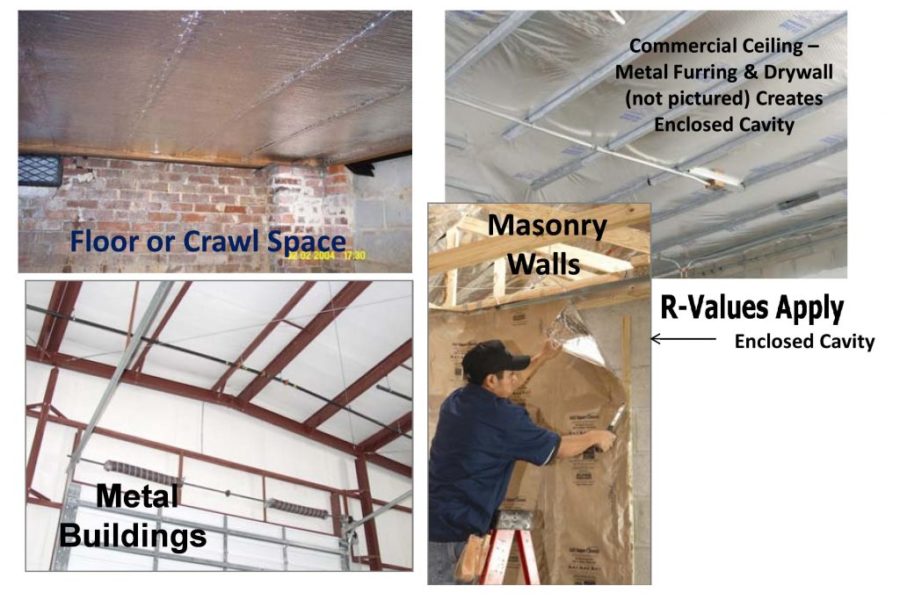

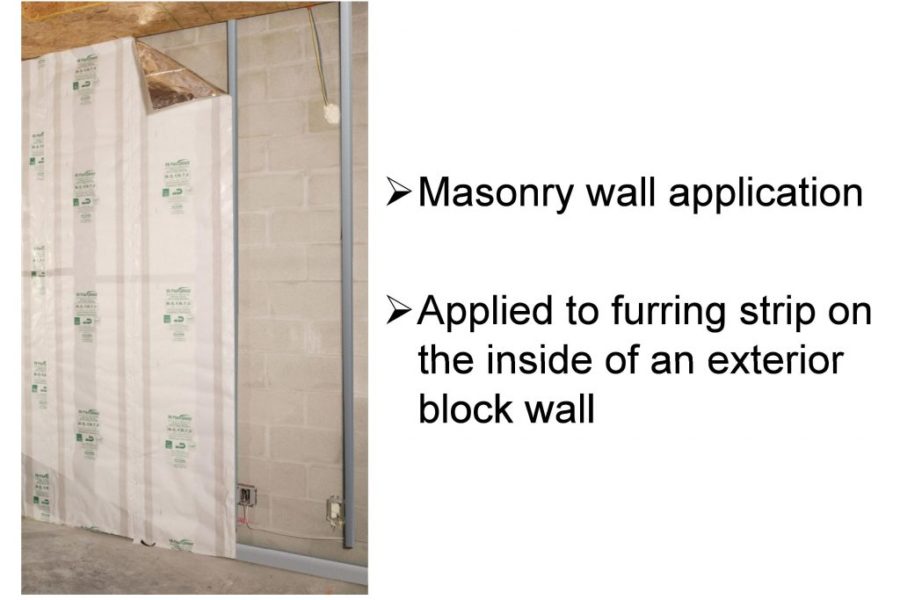

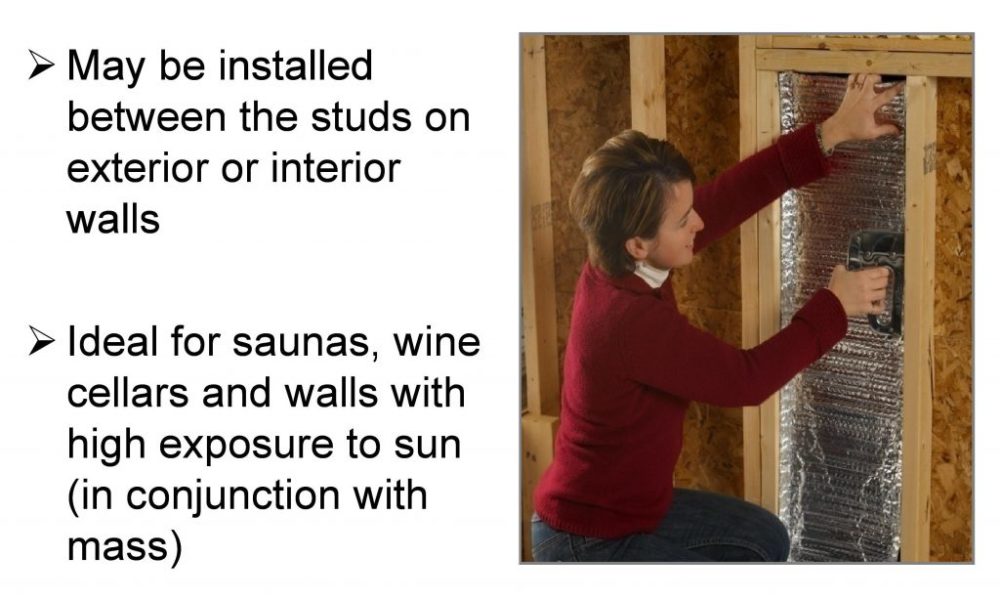

Examples of Radiant Barrier Applications.

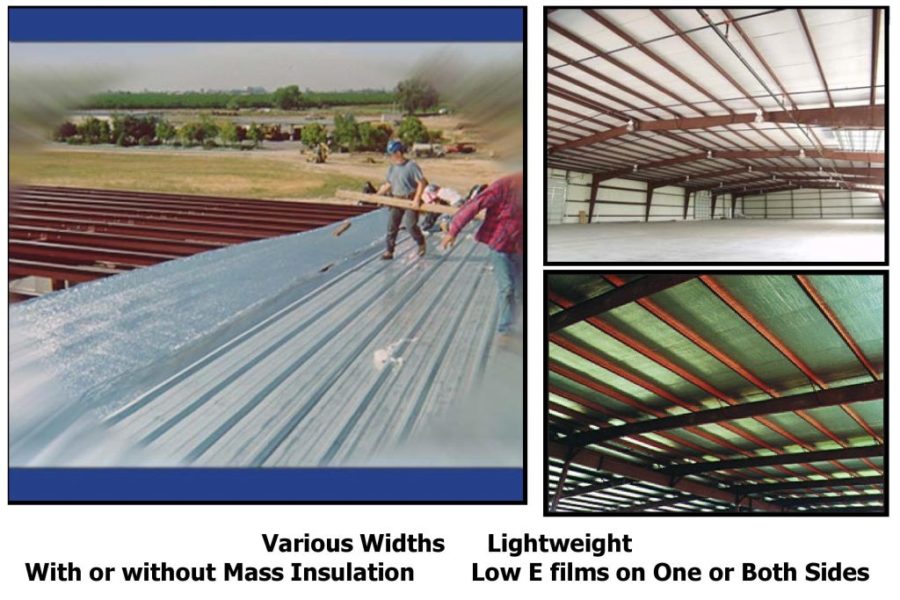

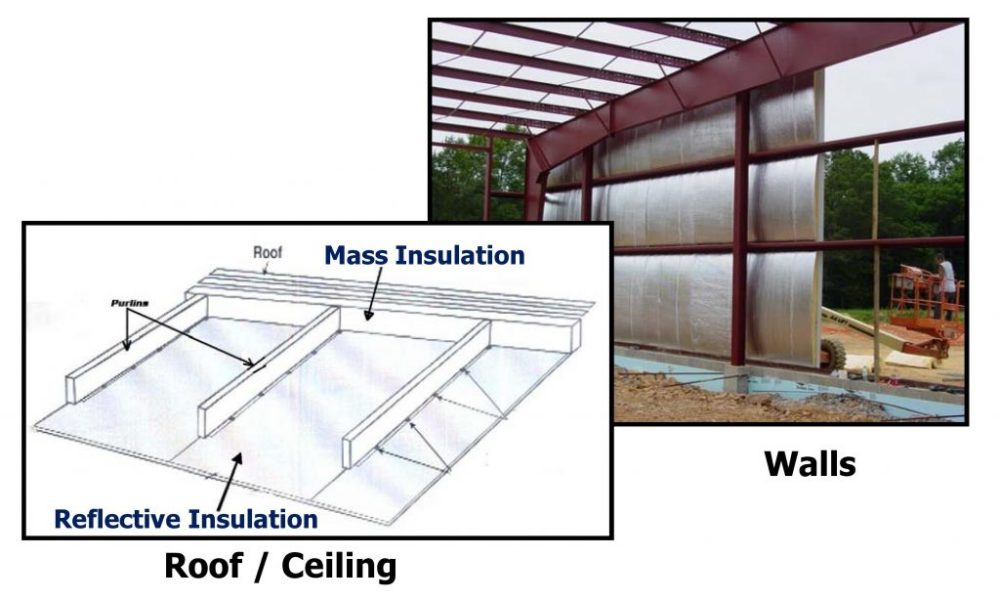

Installation of Reflective Insulation Systems Metal Buildings.

Metal Buildings (NEW)

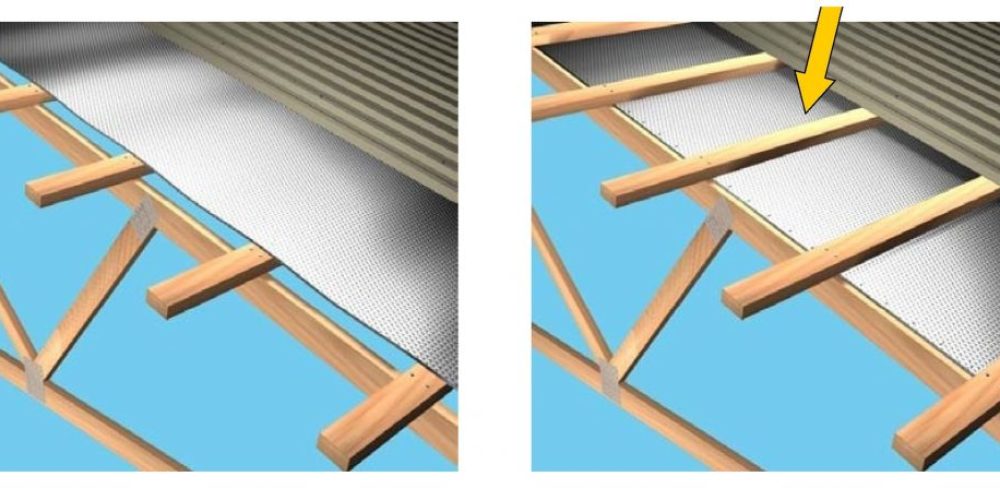

New Construction Roof.

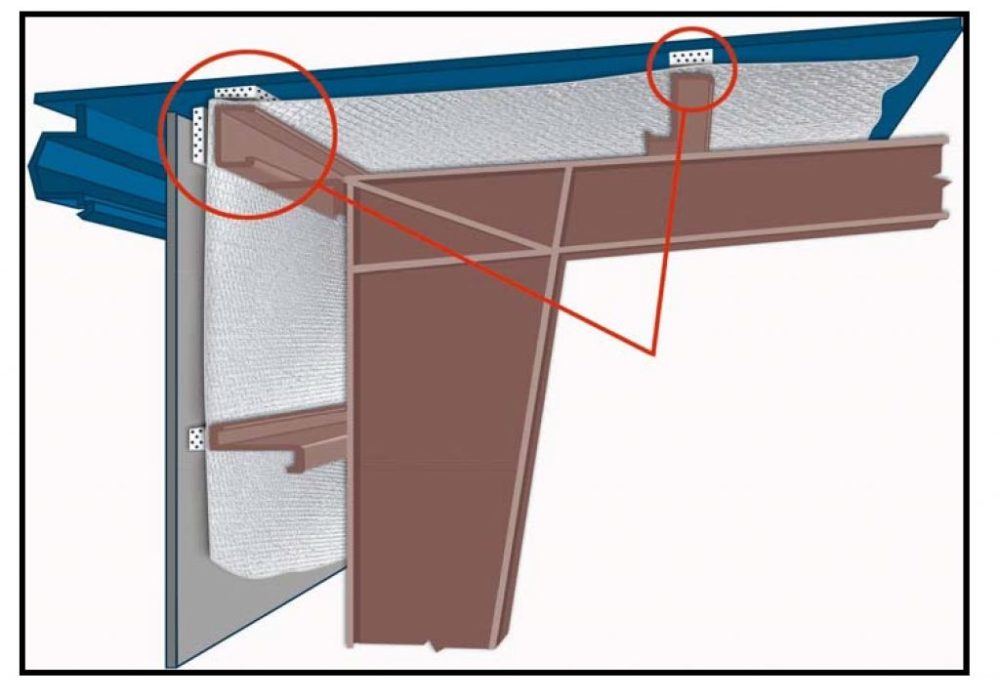

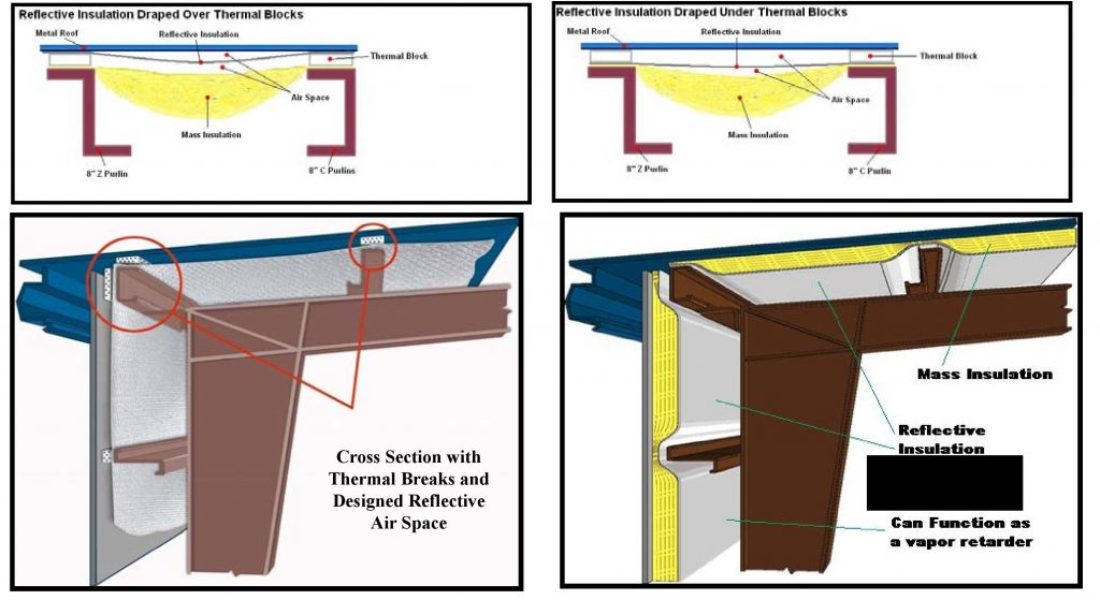

Thermal breaks are important in providing maximum thermal performance of a reflective material.

Cross-Sectional View for New Construction:

Reflective insulation installed over purlins and girts with thermal spacer blocks.

New Construction Roof.

With and Without Thermal Breaks.

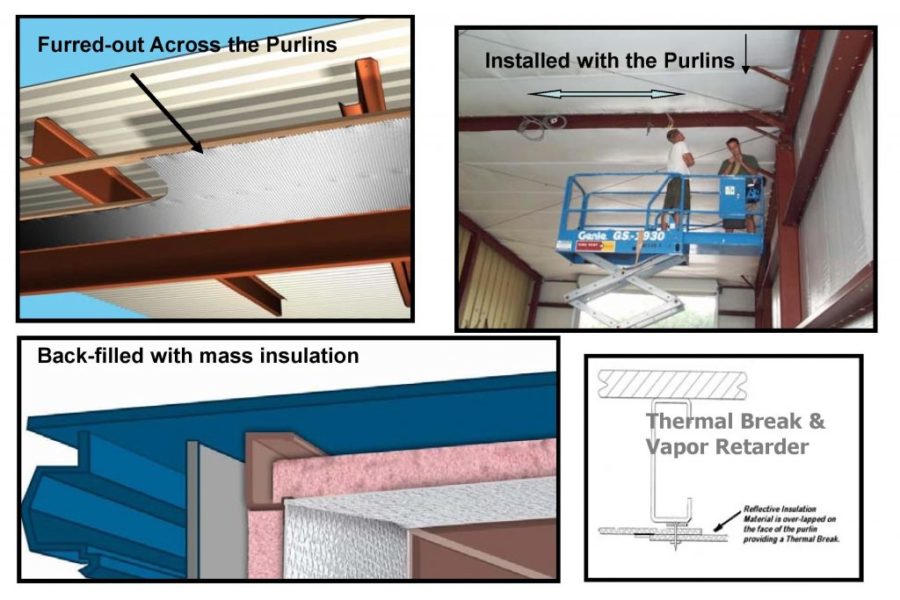

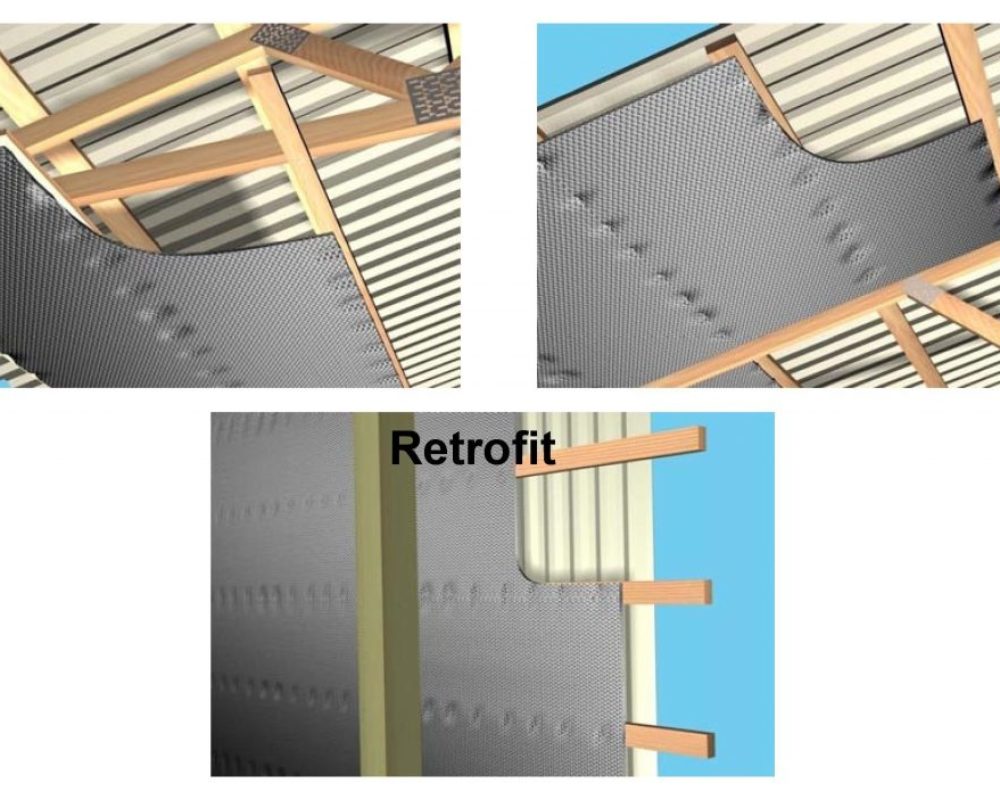

Metal Buildings (Ceilings)

New or Existing

Retrofit

Vapor Retarder

Metal Buildings (ceilings) New or Existings

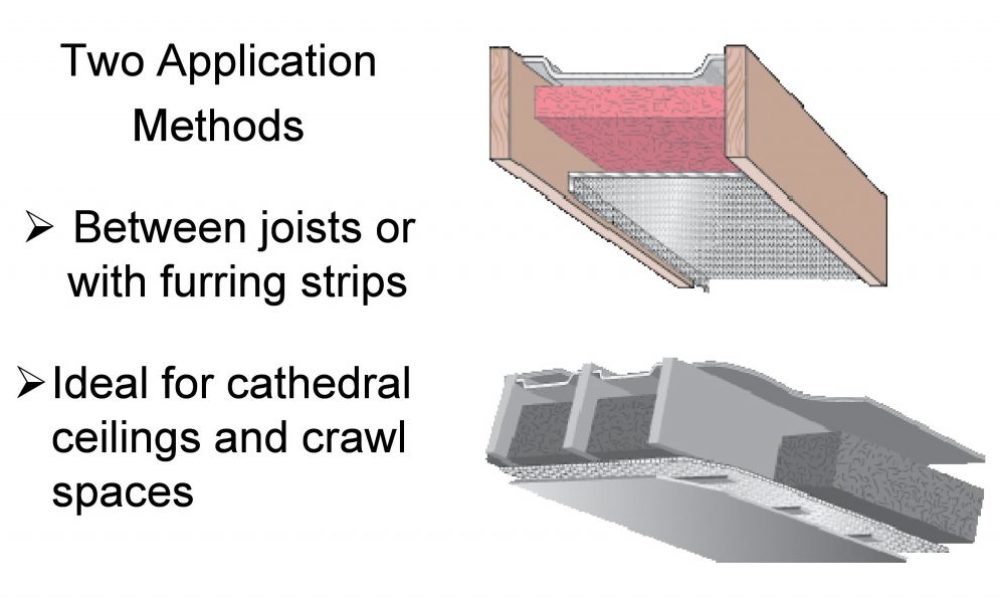

Examples of Reflective Insulation Applications.

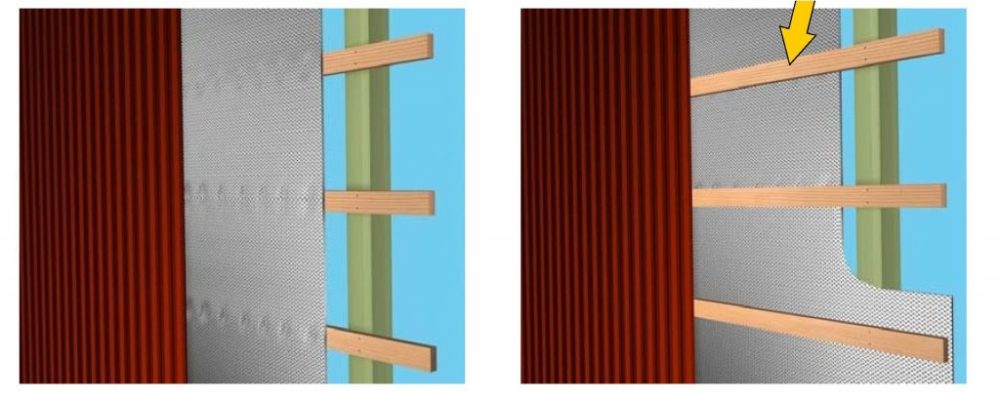

New Construction Walls.

Vapor Retarder

Post Frame - Wall and ceiling.

New Construction Walls

Hybrid Strategies.

Enclose the space below R-19 batt insulation to form a reflective air space.

Install Reflective insulation above the purlins to produce a reflective air space between the mass insulation and the roof panels.

Both strategies increase the thermal resistance between the purlins and add a continuous layer of insulation.

In Combination with Mass Insulation.

Roof Applications